Soft pack cells use aluminum-plastic film as the shell. The good thing is that the size of the battery pack can be changed flexibly. The disadvantage is that the mechanical strength of the single cell is relatively weak, making it difficult to assemble in a conventional way. The interior of existing soft pack lithium batteries is usually filled with gel. This makes the internal heat dissipation poor and subsequent maintenance more difficult.

Metal casing cells usually use aluminum or stainless steel as the casing. The structural strength of the single cell is high, which facilitates capacity expansion. The large capacity of a single cell makes the system composition of the battery relatively simple for maintenance and inspection. Another benefit of a simple system is the increased stability of the internal structure.

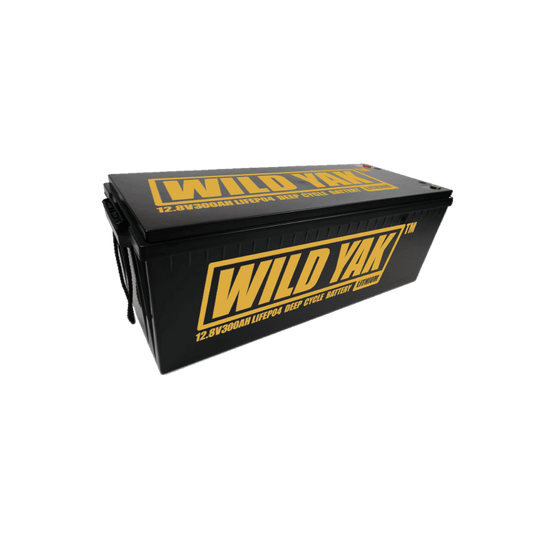

Wild Yak Battery uses rectangular aluminum cased lithium ion cells. Aluminum construction is lighter than stainless steel construction, which results in higher energy density and energy efficiency of the battery.